Tensile fabric structures have become a cost effective but still dramatic way to cover large areas with a clear span shelter.

To date most air supported tensile Fabric Structures that are completely wrapped in fabric are single story or, if more than a single story, they are tensile fabric roofs or tensile membrane roofs on multi-storied compression style structures designed to resist the internal pressure on the fabric or membrane with tensioned cables above the fabric roof. These designs employ Synclastic forms. Synclastic forms are shapes that resemble the top half of an inflated balloon or blimp with downward curves in two directions.

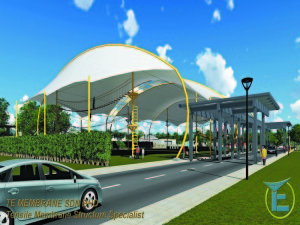

Tensile Fabric Structures specialists working with architects and engineers on the concept and construction side and with the chemical engineers and tensile membrane structure companies on the product development side, have expanded the use of anticlastic forms in architecture to the point where many well-known buildings that grace the current civic skylines worldwide have become landmarks.

In applications where fabric is used in canopies or as sun shades the fabric may be stretched from anchor points on some type of solid perimeter framework, from framework suspended from base buildings or hung from stand-alone columns. The framework must be strong enough to counter the forces of tension required to stretch the fabric into shapes that the fabric will take when the precut pattern is preloaded in tension.

In these cases the roof membrane must be tensile fabric to withstand the forces applied through the woven fabric fibres. The makeup and the coating applied to these fibres comprises the Tensile Fabric and dictates many of its characteristics.

The more grandiose implementations of tensile Fabric Structures and tensile membrane structures incorporate either tensioned cable arrays anchored to standard compression type buildings and covered by a select membrane or a self-supporting membrane of pre-stressed tensile fabric cut to patterns fitting the architect’s vision and stretched through anchor points built into the design of the fabric.

To achieve three dimensional stability in the structure the fabric is stretched or tensioned so that the forces are applied through curves of equal magnitude in opposite directions.

Building owners wishing to make a bold design statement with a signature structure find the freedom of form made possible by tensile fabric and tensile membrane structures one major reason to engage a design team and experienced tensile membrane structure company in the conceptual phases of development.

Probably a close second for consideration by building owners and developers is the cost of incorporating a tensile fabric roof in the design. Owing to the light weight of the fabric roof, costs incurred in building the support structure and deploying the fabric roof are thought to be in the area of 30% less than supporting, and applying a conventional roof system.

Fabric Structures that are completely wrapped in fabric

The fact that the fabric roof is prefabricated and shipped to the construction site ready to be installed greatly reduces the time required to complete the project.

The components and membrane structure along with the additives available to tailor several variables, determine its economical, ecological and operational merits and are of prime importance when considering the capital budget and the ongoing operating costs for the building.

Fabric Structures

The main options for consideration in the base tensile fabrics include a PVC coated woven polyester cloth, a silicone coated fibreglass cloth and a Teflon coated fibreglass cloth. All of these fabrics can be altered with the addition of chemicals that will adjust properties that enhance strength, improve clean-ability, reduce UV degradation, adjust reflection or translucence, add colour and many more.

Of particular concern to building operators are the ongoing costs of maintaining the Fabric Structures, be it Synclastic or Anticlastic.

Where PVC coated polyesters repels dirt, making it easier to keep clean, Teflon or silicon coated fibreglass may require additives to improve this factor. On the other hand, silicone coated fabric offers a much higher fire rating than the PVC coated polyester but there are additives to enhance the fire rating of the PVC product.

Where multi-layer pillow type installations of membrane, often referred to more accurately as foils, can improve insulation they are often specified for their ability to provide a clear, almost glass like appearance. The insulating factor of these roofs can be enhance with the inclusion of a gel between the pillow layers but with a corresponding decrease in the clarity.

Colour can be added to PVC for aesthetics but usually at the cost of higher heat retention and resulting increases in air conditioning and lighting costs.

As the popularity of the tensile fabric style has increased, so the scientists have been challenged to keep pace with the imaginations and design concepts of the tensile Fabric Structures companies and advanced building developers.

Browse this site to know more about Tensile Membrane.

Tag:- Tensile Membrane Structures Company, Tensile Fabric Structures Malaysia, Membrane Structures, , Fabric Roof, Fabric Structures, Tensile Membrane, Tensile Membrane Structures Malaysia, Tensile Membrane Structures, Tensile Fabric Structures