The Grand Arena at the Royal Melbourne Show Grounds was completed in 2006 with a 13,250 square metre Tensile fabric roof using PVC coated Polyester. It covered 8,000 square metres of exhibition space. One of the largest tensile fabric structures in the southern hemisphere.

The Georgia Dome incorporated a Cable supported tensile fabric roof and was the largest cable supported dome in the World.

The London Olympic Stadium could seat up to 80,000 people under a tensile fabric roof of PVC coated polyester and wrapped with a tensile Membrane Structures 20 metres high by 900 metres around. At the time of its completion in March 2011 it was the third largest stadium in England.

B.C. Place Stadium sports the largest cable supported retractable roof in the world. Completed in 2011 the architects, engineers and tensile fabric structure specialists used 36 masts around a compression ring to resist the tension on the 35 kilometres of cable and 76,000 square metres of tensile fabric that make up the 135 ton retractable fabric roof.

Completed in 1983, the Talisman Centre was the first translucent insulated roof in the world. In 2011 the roof was replaced with a new Teflon coated fiberglass outer layer of tensile fabric. The new roof incorporated a new gel known as Nanogel between the outer tensile fabric layer and the inner Membrane Structures to improve the translucence and insulating factor of the fabric roof while maintaining the original appearance of the building.

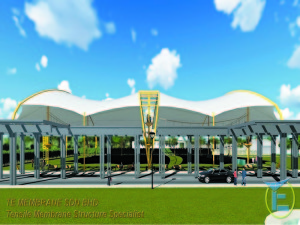

Tensile Membrane Structures stretched on a steel frame

Architects and designers are embracing the Tensile Fabric Structure for its flexibility in conceptual design and the ability to add spectacular free form highlights to their projects.

The projects mentioned above are highlights of the skylines that they inhabit and in many cases have become landmarks and a source of civic or national pride.

There are however far more tensile fabric structures that we observe without remark in our day-to-day commutes, our neighbourhood walks and highway travels. They are universal and they become more widespread each year.

In their smallest form we see them in the driveway of the three car family with a two bay garage. The tensile fabric covered steel frame that looks a bit like a tunnel but sheds the weather and expands the storage space.

The currently popular awning sign is another example of the tensile Membrane Structures stretched on a steel frame.

Membrane Structures

A step up from these storage tunnels would be the party tent. The frame is usually based on steel posts and frame but in most designs the tensile fabric roof is hung from a mast supported by tensioned cables. In other forms of similar size, cable and steel frames support striking looking canopies and walkway covers and shelters that utilize tensile fabric for shelter from rain or sun.

Air supported permanent or temporary domes for larger construction or special events are cost effective alternatives. They are quickly set up and taken down and they are about one third the cost of a traditional brick and mortar style building. Air supported tensile fabric structures are scalable from about 300 square metres to large multi-sport venues. In the case mentioned above the B C Place retractable cable supported roof replaced an inflated tensile fabric roof.

Although air supported tensile fabric structures can sustain wind speeds upwards of 250 kilometers per hour and resist snow loads near 10 kilograms per square metre, The cable or truss supported style seems to be evolving as the favoured style for larger and more permanent fabric structures.

Moving up in scale from the canopies and open shelters we often see highway sand a salt sheds adjacent to mountain roads. Usually constructed with a concrete or heavy wood base to sustain the impacts from heavy equipment moving the product, these sheds are most often topped with a fabric roof tensioned over steel trusses. This type of building is also becoming popular in agriculture to protect harvested crops or machinery.

Owing to the light weight of the tensile fabric structures or tensile Membrane Structures, large spans can be attained without the need for intermediate supporting posts. For this reason they are increasingly favoured for sports venues, riding arenas and concert venues. The substantial cost savings in construction coupled with the environmental advantages such as natural light have made this an ever expanding style that is being pushed to elevated levels with each new architectural concept. The ease of erection, light weight and the portability or the style make it a sought after variation for small enclosed shelters and canopies.

for reading about Tensile Fabric Structures Specialist.

Tag:- Tensile Membrane Structures Company, Tensile Fabric Structures Malaysia, Membrane Structures, , Fabric Roof, Fabric Structures, Tensile Membrane, Tensile Membrane Structures Malaysia, Tensile Membrane Structures, Tensile Fabric Structures