Tensile Fabric Structures Installation

As we commit our expertise and align it with our client’s goals, we advance our knowledge, skills and planning in terms of technology in executing the installation of tensile fabric roof.

The success of a project is the project planning and coordination at site. From traffic diversion, road closures, heavy vehicle planning to accommodate cranes and sky lift, working platforms – whatever the fabric installation method statement, our team is fully equipped to ensure a safe installation and thorough handover.

Installing fabric structures takes a great deal of skill and experience. The primary objective is understanding of the design and to produce a logical sequence in the structural steel installation and fabric installation.

Our team of experienced fabric riggers are trained and undertook different types of installation works, involved different type of materials and design locally and internationally. Understanding risk management and safe work environment are important process. Including We understood the use of machinery, equipment and special tools in membrane installation. Toolbox & safety briefing, risk assessment and method statements are part of our installation quality standard.

Lastly, we observe strict rules and safety precautions with the setting out and checking, structural steel erection and final fabric installation. We practice care and housekeeping during the fabric installation. During the final stage of the installation, tension of the fabric has to be carried out in a specific manner & sequence. The final tension is according to design as specified in the engineering drawings. The tension follow the right compensation value set during the design and the correct amount of tension prevents fabric movement and deflection under wind, rain and snow loads.

Our installation team exists out from a core of very experienced membrane installation team and experienced membrane installation supervisors & personnel.

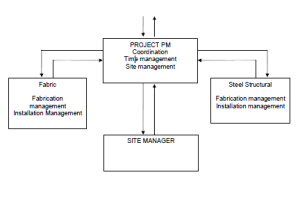

Below is our simple flow of coordination within our key teams for faster turnaround of the project completion in membrane structures:

Our installation team makes sure that we have all we need to execute and finish each project.